Installing a Transparent Splicing Screen: Key Precautions and Two Critical Scenarios to Consider

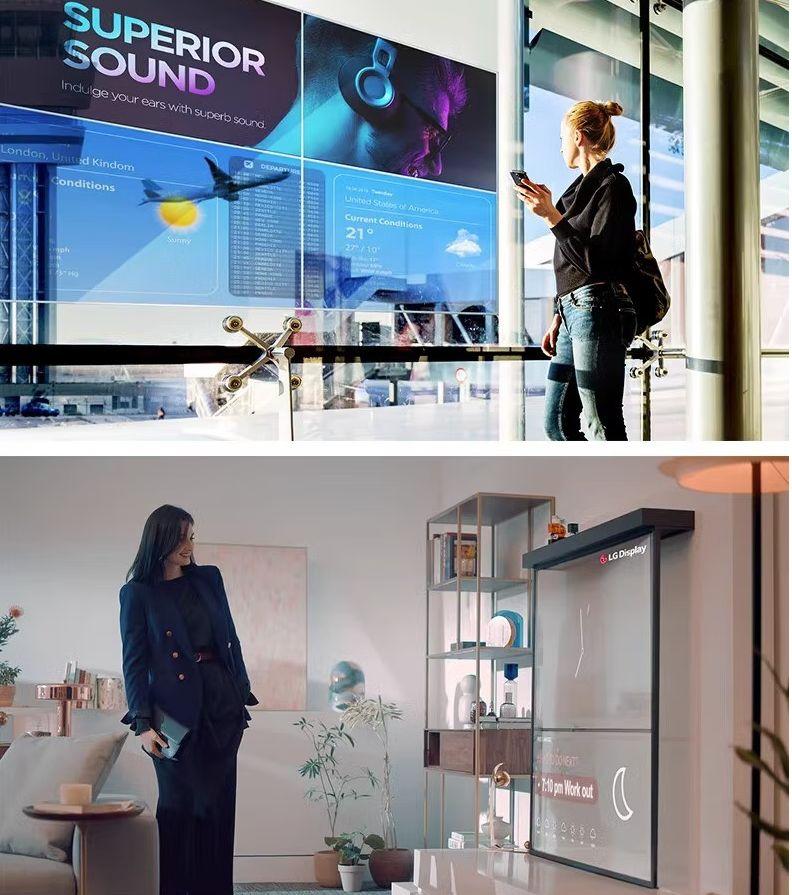

As an advanced display technology, transparent splicing screen is widely used in various commercial occasions. Its unique transparency and flexibility bring a new visual experience to the display. YHF will use this platform to introduce the installation steps, precautions and installation methods of transparent splicing screen in special application scenarios.

1. Installation steps

Preparation: First, confirm the installation environment, including site size, load-bearing capacity, etc. Then, prepare the required installation tools and materials, such as screwdrivers, levels, brackets, etc.

Install the bracket: Choose the appropriate bracket type according to the screen size and requirements. Assemble the bracket according to the instructions and fix it in the specified position. Make sure the bracket is level and stable.

Screen installation: Place the screen on the bracket and fix it with screws. Make sure the screen fits tightly to the bracket without shaking.

Connect the lines: Connect the power lines, signal lines, etc. according to the instructions in the manual. Make sure the lines are firmly connected and there are no exposed parts.

Debugging and testing: After completing the line connection, debug and test. Make sure the screen displays normally without color difference, flickering, etc. At the same time, check whether the operation of the control system meets the requirements.

2. Precautions

Safety first: During the installation process, be sure to pay attention to personal safety to avoid accidental injuries caused by improper operation.

Follow the instructions: Install strictly according to the instructions to avoid equipment damage due to incorrect operation.

Keep clean: During the installation process, keep the screen and line clean to avoid dust and debris affecting the display effect.

Regular inspection: After the installation is completed, regularly check the screen and line to ensure the normal operation of the equipment.

3. Installation steps for special application scenarios

Outdoor display: In outdoor display, the transparent splicing screen needs to withstand harsh environments such as wind and rain. To ensure stability and safety, it is recommended to use a special waterproof and dustproof bracket and fix the screen on a solid structure. At the same time, consider installing a sunshade to reduce the impact of direct sunlight on the screen.

Curved surface installation: In curved surface installation, you need to choose a screen and a special bracket that are suitable for the curved surface. Adjust the position of the bracket according to the curvature of the curved surface to ensure that the screen fits tightly to the curved surface. At the same time, pay attention to the reasonable layout of the lines to avoid excessive tension or pulling.

YHF reminds you: The installation of transparent splicing screens needs to follow certain steps and precautions, and choose the appropriate installation method according to different application scenarios. Through the correct installation method, the advantages of transparent splicing screens can be fully utilized to bring customers an excellent visual experience.